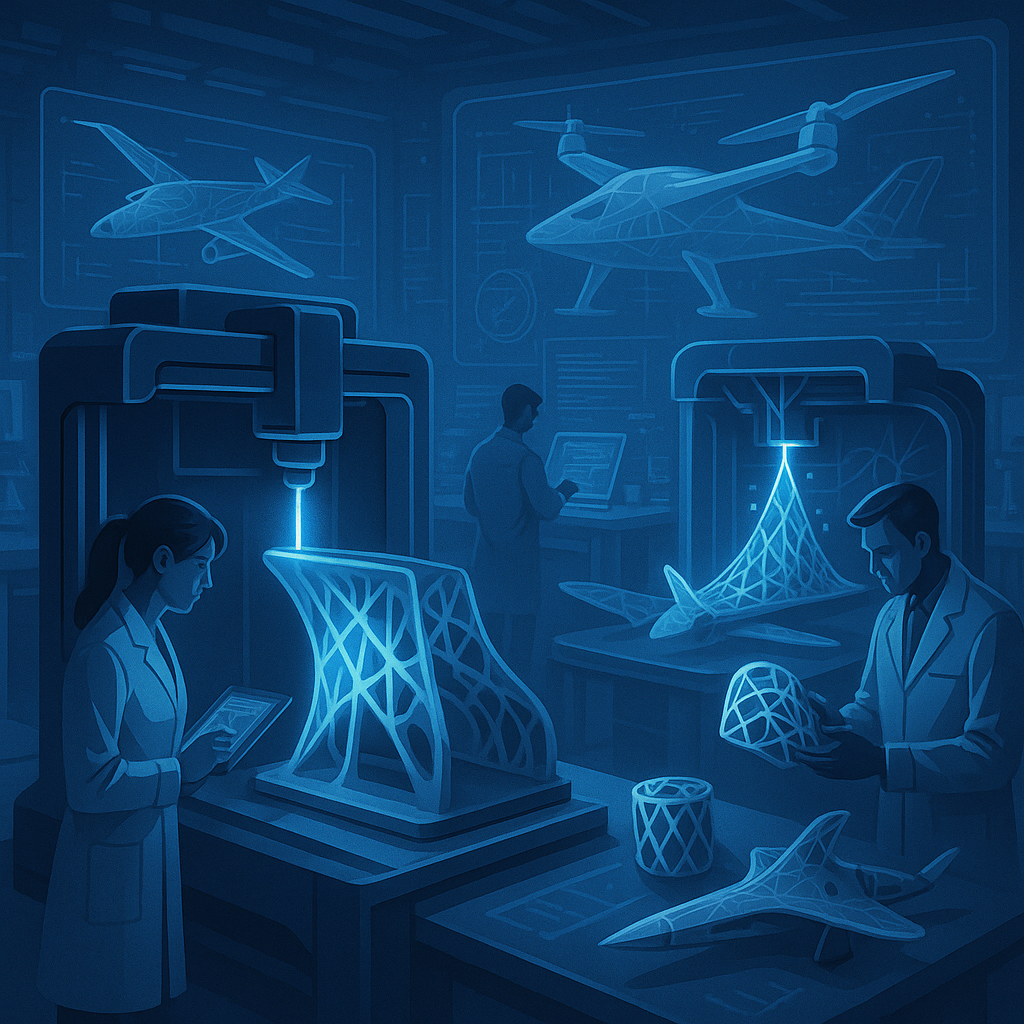

Additive manufacturing — also called 3D printing — has a significant influence on airplane and spacecraft construction. This technology enables companies to produce lighter stronger, and more efficient parts quicker and cheaper. Let’s dive into what additive manufacturing means and why it’s becoming crucial in aerospace.

🧠 What Is Additive Manufacturing?

Additive manufacturing is a technique where machines construct an object one layer at a time. Traditional manufacturing cuts a part from a larger material block. But additive manufacturing differs — it adds the necessary material resulting in much less waste.

🚀 Why the Aerospace Industry Loves 3D Printing

In aerospace, every gram of weight counts. Lighter parts lead to less fuel use and better efficiency. Here’s why additive manufacturing has a revolutionary impact on the industry:

- ✅ Less material wasted — You use what you need.

- ✅ More complex shapes — You can create designs that weren’t possible before.

- ✅ Faster turnaround — You get new prototypes in no time.

- ✅ Cost savings — You cut down on material and labor expenses.

🧩 Real-World Uses in Aerospace

Additive manufacturing is already leaving its mark. Companies use 3D printing to make:

- 🔧 Engine parts that withstand extreme heat.

- 🧭 Brackets and supports that reduce weight without losing strength.

- ✏️ Prototypes that enable engineers to test new designs quicker.

These lighter and more efficient components allow planes to fly longer distances and consume less fuel — which also cuts down on pollution.

🔮 The Future of Aerospace Design

As 3D printing technology advances, we’ll witness more breakthroughs in the aerospace industry. Quicker printers and new materials will give engineers the ability to design shapes that were impossible before. This means faster development of next-gen aircraft and spacecraft — all focusing on safety, performance, and sustainability.