Automation plays a big role in changing industries, and Autonomous Mobile Robots (AMRs) lead this shift. Unlike traditional Automated Guided Vehicles (AGVs), which stick to set paths, AMRs rely on sensors, cameras, and AI to move freely making them smarter more flexible, and productive. From warehouses and factories to hospitals and retail stores, AMRs are changing how businesses run.

🤖 What Are Autonomous Mobile Robots (AMRs)?

AMRs are smart robots that move on their own, without needing tracks, floor markings, or fixed paths. They use advanced mapping tech and make decisions in real time to spot obstacles, change routes, and learn from their surroundings. This makes them perfect for ever-changing environments where getting things done and being flexible matter most.

How Do AMRs Work?

🔹 Sensors & Cameras – Spot surroundings and dodge obstacles. 🔹 AI & Machine Learning – Look at live data to make navigation better. 🔹 Cloud Connectivity – Pass info across networks to perform at their best. 🔹 Autonomous Decision-Making – Change paths based on shifting environments.

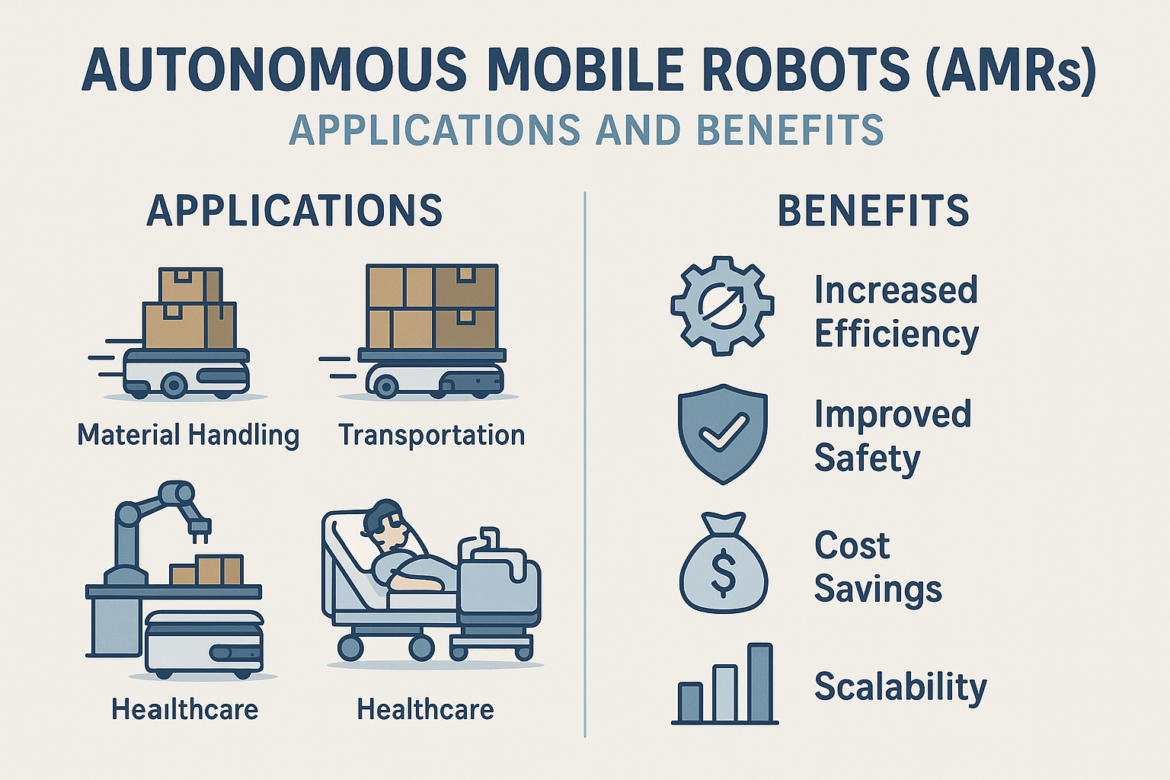

🏭 Where Are AMRs Used?

1️⃣ Warehousing & Logistics

📦 Managing Inventory – AMRs keep tabs on stock levels as they happen cutting down on mistakes. 🚀 Fulfilling Orders – Robots pick and pack faster boosting productivity. 🚚 Transporting Goods – AMRs move stuff around warehouses easing the load on workers.

🔹 Example: Amazon’s fulfillment centers use AMRs to automate how they store and fetch products, which makes processing much quicker.

2️⃣ Manufacturing & Assembly

🏭 Material Transport – AMRs move raw materials and finished goods . 🔩 Assembly Line Support – AMRs bring components to workstations at the right time. 📷 Quality Control – AMRs with AI check products for flaws cutting down on waste.

🔹 Example: Car makers use AMRs to carry parts between assembly lines keeping production running .

3️⃣ Healthcare

💊 Delivering Medications & Supplies – AMRs carry medical supplies easing staff workload. 🦠 Hospital Disinfection – Some AMRs clean rooms with UV light to stop infections. 📄 Administrative Support – AMRs manage patient records and logistics to boost productivity.

🔹 Example: Hospitals employ AMRs to lower the risk of infections and boost patient care by taking care of non-clinical jobs.

4️⃣ Retail & Customer Service

🛒 Shelf Scanning – AMRs check how much stock is left letting staff know when it’s time to restock items. 🤖 Customer Assistance – Robots lend a hand to shoppers looking for products making their shopping trip better.

🔹 Example: Big retailers like Walmart use AMRs to keep an eye on inventory and run their stores more .

🔥 Main Perks of Using AMRs

🚀 1. Ramping Up Productivity

AMRs handle routine jobs letting workers focus on trickier tasks. In warehouses, they cut down on walking time speeding up order processing.

⚡ 2. Flexibility & Adaptability

Unlike AGVs, AMRs don’t need set routes. This makes them great for places that change, like growing warehouses or shifting seasonal needs.

🦺 3. Improved Safety

AMRs come with tech to avoid bumps making workplaces safer as they move around people and things without crashing.

💰 4. Cost Savings

While AMRs need upfront money, they cut down on worker expenses and make fewer mistakes. This leads to money saved over time and a quicker payback on what you put in.

📈 5. Scalability

Companies can add more AMRs without much trouble as they expand making them a smart choice for automation that won’t become outdated.