What Is a Dark Factory?

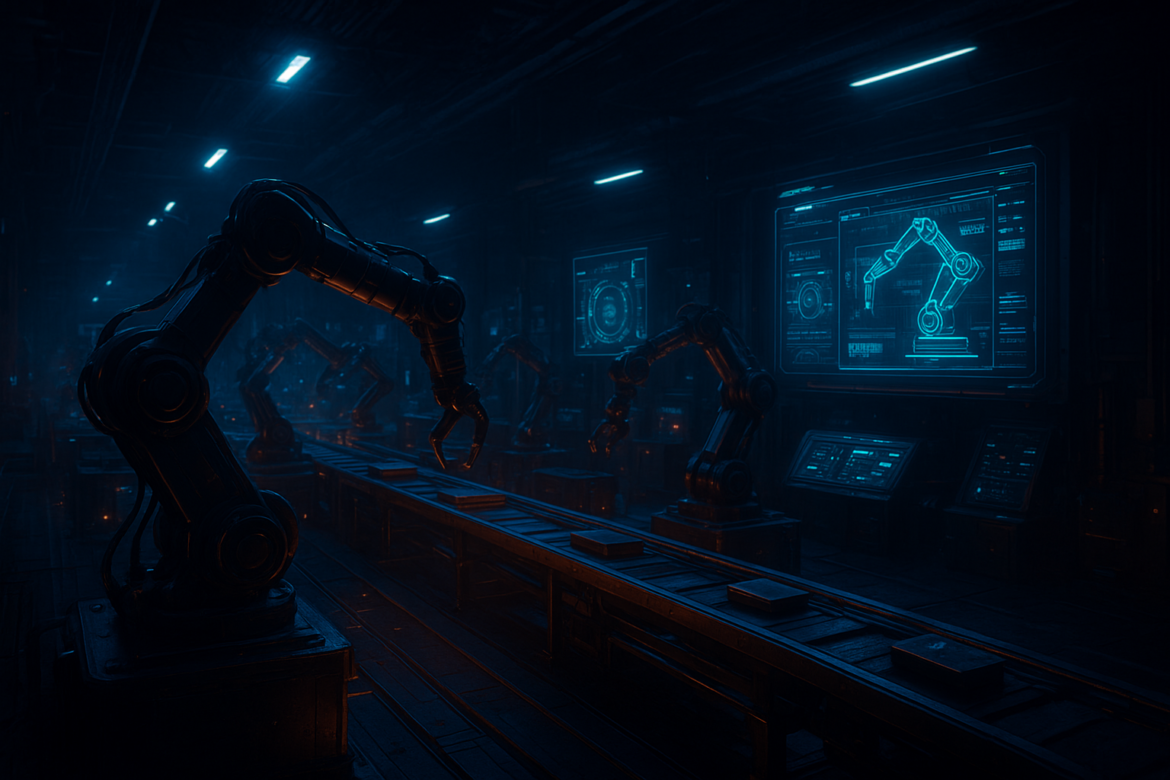

A dark factory is a factory that is fully automated and has no human workers on the production floor. Robots, machines, and Artificial Intelligence (AI) carry out the entire operation. The factory can operate all the time—day and night—without the need for human intervention. Since the factory is free of humans, it does not even require lights, hence the name “dark” factory.

Why Are They Called “Dark” Factories?

Dark factories are named so because they can function without the use of lighting. Machines and robots do not require light for their operation, so everything is done in the dark. There is also no demand for air conditioning, restrooms, or safety equipment for workers. Only machines, sensors, and computer systems are taking care of the whole operation silently and continuously.

How AI Works Inside a Dark Factory

Artificial Intelligence serves as the brain of a dark factory. AI determines the ways machines should work, how production should be speeded up, and it also finds solutions to resolve problems. AI monitors data coming from various sensors and it makes the smartest decisions without delay. AI enables the equipment to learn from their errors and to enhance their performance without any human assistance.

Role of Robots in Dark Factories

Robots are the primary laborers in dark factories. They execute operations such as the assembly of parts, welding, cutting, packing, and the transportation of goods from one place to another. These robots perform the tasks faster and more accurately than human beings. They do not get exhausted, and they can constantly do the same job without making mistakes.

How Quality Is Checked Using Computer Vision

Inspection of product quality in dark factories is done by AI-powered cameras instead of human workers. These cameras examine every product in detail and detect cracks, scratches, shapes issues, or the absence of parts. In case a defect is present, the system gets rid of the defective product automatically. The main goal of this measure is to ensure the highest quality level with almost no mistakes.

Predictive Maintenance Using Machine Learning

Machine maintenance in dark factories is done with the help of machine learning. Sensors gather information like temperature, vibration, and speed of a machine. AI analyzes this data and predicts the time when a machine is going to break down. As a result, companies are given the opportunity to repair machines before they actually break thus saving money and avoiding production delays.

Automated Supply Chain and Inventory

In addition, AI is the one who regulates the supply chain in a dark factory. It is in charge of ordering raw materials automatically, handling storage, and facilitating delivery via robots and automated vehicles. This is what keeps production going without stoppages or shortages. Everything is accomplished through intelligent software programs.

Use of Digital Twins in Dark Factories

A digital twin refers to a virtual instance of the real factory generated via AI. Engineers can experiment with new concepts, machine settings, and production changes using the digital version before implementing them in the actual factory. It provides the advantages of risk reduction, cost saving, and efficiency improvement.

Benefits of Dark Factories

Dark factories provide lots of major benefits. They do the work day and night, without any breaks, thus the speed of production is greatly increased. They make products with a high degree of precision and consistency. The possibility of human errors is almost completely eliminated. Businesses save a significant amount of money over time as labor costs are reduced. Above all, workers are kept away from hazardous environments.

Challenges of Dark Factories

However, the power of dark factories is limited due to their challenges. The initial investment is extremely expensive. They require robust cybersecurity measures as hackers might target the automated systems. If AI systems malfunction, production can come to a complete halt. In addition, there are worries about loss of jobs for factory workers.

Real-Life Examples of Dark Factories

Several major corporations have already implemented dark factory systems. In Japan, some factories operate for months without human intervention. In Germany and the USA, electronics and car production plants employ extensively automation. These factories produce large volumes with very little human involvement.

Difference Between Smart Factories and Dark Factories

Smart factories involve humans working together with machines. Dark factories operate without humans on the production floor. Smart factories still have lights and worker facilities, while dark factories do not. Both use AI and automation, but smart factories are a step away from complete automation, whereas dark factories are fully automated.

Future of Dark Factories

Eventually, the adoption of dark factories will spread to other industries such as automobile, electronics, medical equipment, and aerospace manufacturing. Fully automated factories will be the norm rather than the exception worldwide due to the development of AI, robotics, 5G, and the Internet of Things.

Impact on Human Jobs

Dark factories will lessen the need for manual labor, however, they won’t be the end of human jobs because new jobs will be created. There will still be demand for people as AI engineers, robotics technicians, data analysts, and automation experts. Future jobs will be centered more around technology and system management rather than physical labor.

Why Dark Factories Are Trending in 2025

Dark factories have become popular because companies are looking for faster production, lower costs, better quality, and improved safety. Taking into account the rising labor costs and competition, businesses are using AI-driven automation as a way to keep up with or get ahead of competitors in the market.

Conclusion

Dark factories demonstrate how production will be done in the future. With the help of AI, robots, and automation, factories can run without the need for human workers on the shop floor. Acknowledging that there are issues such as high costs and job uncertainties, the advantages of speed, precision, safety and efficiency make dark factories one of the most significant inventions of the modern industrial era.