As online shopping booms, warehouses face more work than ever. To keep pace many companies now use robots to speed up tasks and boost accuracy. These clever machines make warehouse jobs easier and help businesses save time and cash. In this blog, we’ll explain how robotics is changing warehouse work in a clear simple way.

What Do Warehouse Robots Do?

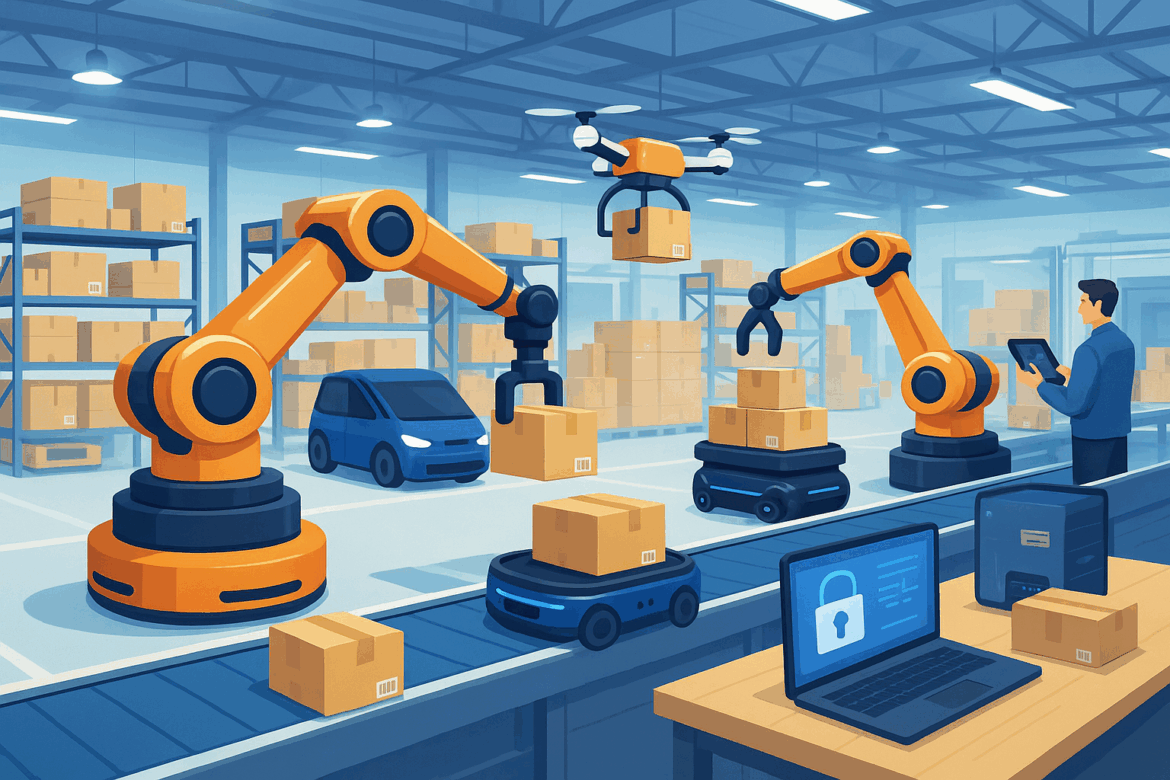

Warehouse robots are machines that assist with daily chores like picking items, packing boxes sorting products, and moving stuff around. Some robots work with people, while others can handle jobs on their own.

Common Types of Robots in Warehouses:

- AGVs (Automated Guided Vehicles): These robots stick to fixed routes to transport items between different locations.

- AMRs (Autonomous Mobile Robots): They navigate throughout the warehouse using their built-in cameras and sensors.

- Robotic Arms: These machines pick up, select, or package items with speed and precision.

- Drones: These flying robots excel at checking stock on high shelves or in big warehouse areas.

Why Warehouses Have Started to Use Robots

1. To Speed Up Operations

Robots can work around the clock, which helps warehouses to ship more orders in a shorter time.

2. To Cut Down on Errors

Robots help to reduce mistakes made by humans when selecting and packaging items.

3. To Save Money in the Long Run

Although robots cost a lot to purchase, they help companies save money over time by lowering labor expenses and cutting down on waste.

4. Monitoring Inventory

Smart robots can scan products and provide instant updates on stock levels, which reduces unexpected shortages.

5. Enhancing Workplace Safety

By taking on heavy or repetitive jobs, robots lower the chance of human workers getting hurt.

Real-World Examples

- Amazon employs numerous robots to transport product shelves, which speeds up order processing .

- Walmart is experimenting with robots to assist in checking store shelves and keeping track of inventory.

- Small businesses are also getting involved by leasing robots through services known as Robotics-as-a-Service (RaaS).

Things to Keep in Mind

- High Starting Cost: Robots require a big investment. Companies need time to see the full payback.

- Tech Setup: Companies must set up robots to work well with their current software and systems.

- Training Staff: Workers need to learn how to use and take care of these machines.