🌍 Introduction – Why Automation Has an Impact on Change

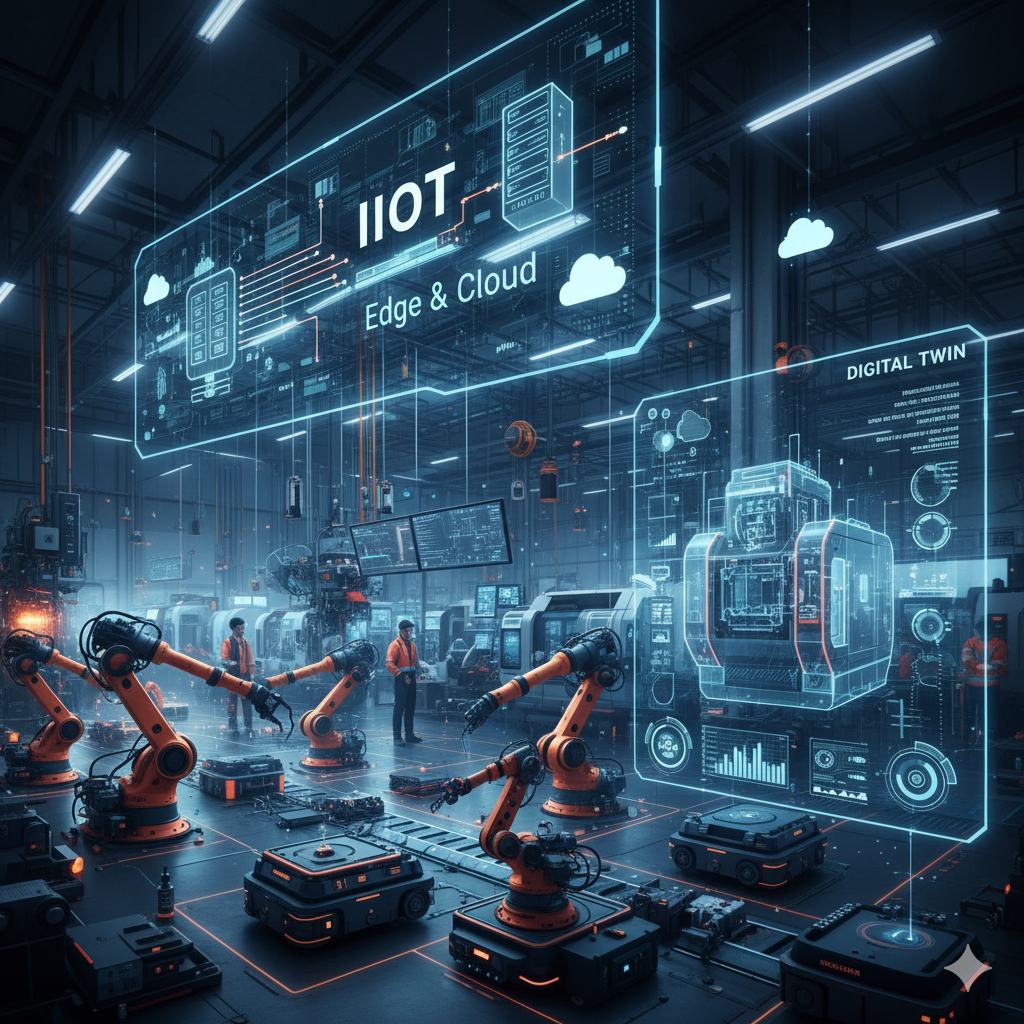

Modern factories go beyond just machines and workers. They’re evolving into smart factories where devices, sensors, and software collaborate. This shift stems from three major technologies:

- IIoT (Industrial Internet of Things)

- Edge & Cloud Computing

- Digital Twins

These developments are boosting industry speed, safety, and productivity. Let’s break them down in plain language.

🔌 What is IIoT (Industrial Internet of Things)?

Picture IIoT as a web of internet-connected smart machines.

- Machines have sensors that monitor data such as heat, speed, and energy.

- This data goes to managers and engineers .

- Companies can foresee issues before they occur and boost production.

👉 Example: A factory motor alerts workers if it’s getting too hot. Fixes can happen before it stops working, saving both money and time.

Why it matters: IIoT helps companies cut downtime lower costs, and enhance safety.

⚡ Edge & Cloud Computing – How They Work Together

Factories create tons of data every second. To manage it, companies use Edge Computing and Cloud Computing.

- Edge Computing: Handles data right on the machine or nearby computer.

- Lightning-fast response.

- Ideal for jobs that need quick decisions such as robots or quality checks.

- Cloud Computing: Keeps data on distant servers.

- Perfect for holding huge amounts of information.

- Helpful to analyze long-term trends, create reports, and share data among teams.

👉 Example: A robot checks a product using edge computing. At the same time, the cloud saves production reports for managers to examine later.

Why it matters: Edge means speed, Cloud means storage and analysis. Together, they make automation strong.

🏭 Digital Twins – Virtual Factories

A Digital Twin resembles a virtual replica of an actual machine or factory.

- It mirrors the appearance and functionality of the real system.

- Engineers can experiment with new concepts on the digital version before altering the actual one.

- Digital twins employ IIoT data to remain current in real time.

👉 Example: Prior to setting up a new assembly line, a company creates a digital twin to understand its operation, energy consumption, and potential issues.

Why it matters: It cuts costs, minimizes errors, and accelerates innovation.

✅ Conclusion – The Future of Smart Industries

Industrial automation progresses towards a linked and smart future.

- IIoT gives machines a way to communicate.

- Edge & Cloud make data quick and valuable.

- Digital Twins allow industries to plan before taking action.

Companies that adopt these technologies will lead the pack by becoming more efficient, secure, and eco-friendly.