What is Robotic Welding?

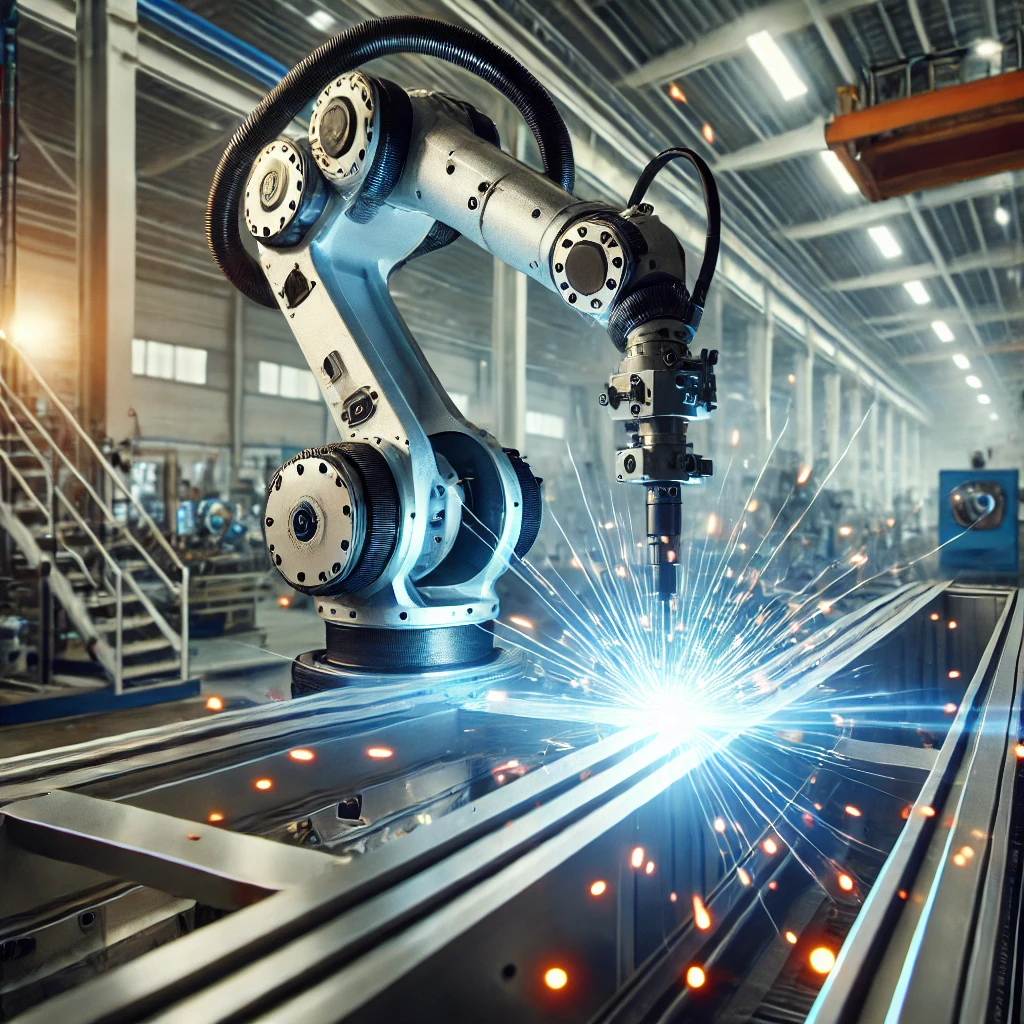

Robotic welding is the use of robots to perform welding tasks, replacing human workers. These robots are equipped with specialized tools and programmed for precision. They can perform various welding techniques, such as arc welding, spot welding, and laser welding, making them ideal for industries like automotive, aerospace, and manufacturing.

Why is Robotic Welding Important?

1. Better Accuracy

Robots offer high precision and can repeat the same high-quality welds without mistakes, ensuring reliability in industries like automotive and aerospace where accuracy is critical.

2. Faster Production

Robots can work continuously without breaks, speeding up production times and increasing efficiency, which is crucial for industries demanding high output.

3. Cost Savings

While the initial cost of robotic systems may be high, they reduce labor costs, minimize errors, and lower safety expenses, making them cost-effective in the long run.

4. Improved Worker Safety

Welding can be dangerous, involving heat and toxic fumes. Robots take on these hazardous tasks, keeping human workers safe from injury.

Where is Robotic Welding Used?

- Automotive Industry: Robots are used for assembling car bodies and other parts, improving production efficiency.

- Aerospace Industry: Robots ensure high-quality, precise welds for aircraft and spacecraft.

- Construction and Heavy Machinery: Robotic systems are used to weld large components for construction equipment and machinery.

Key Components of a Robotic Welding System

- Robot Arm: Positions the welding tool.

- Welding Torch: Melts and fuses metals.

- Control System: Programs the robot for specific tasks.

- Sensors and Cameras: Monitor and adjust the welding process.

The Future of Robotic Welding

With advancements in AI, robotic welding systems are becoming smarter, learning from past actions, adapting to new tasks, and improving efficiency. This makes them even more precise and adaptable to different materials and production needs.