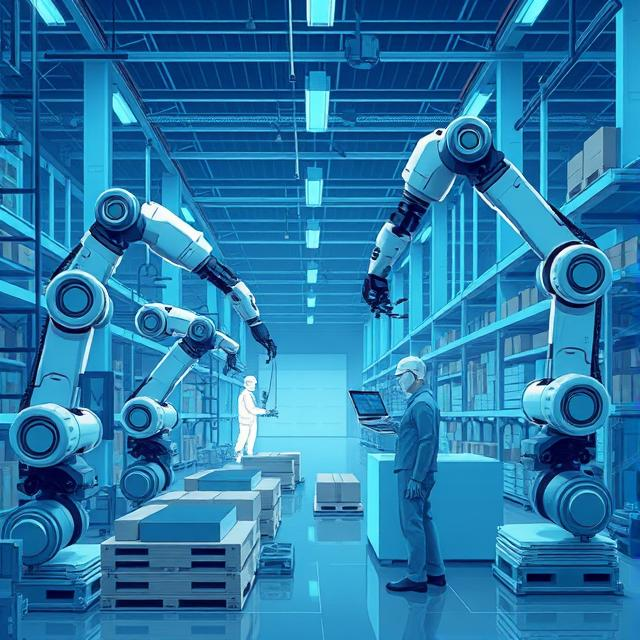

In our fast-changing world, automation has become essential. Collaborative robots, or cobots, work alongside humans. Unlike old industrial robots that need safety barriers, cobots have smart sensors and clever software. This makes them safe, adaptable, and highly productive in modern workplaces.

The Rise of Cobots

Cobot demand has exploded . As technology advances and labor costs increase, companies seek automation solutions to boost output without spending too much. Cobots are changing the game for small and mid-sized businesses that need affordable automation to keep up with competitors.

How Cobots Work

Cobots use advanced sensors and AI-driven algorithms to spot and avoid obstacles making sure they work with humans. They handle tasks that are repetitive or hard on the body, which lets human workers turn their attention to more important creative, and big-picture parts of their jobs. Also, cobots fit into existing work setups, which makes them a flexible and easy-to-use option for many different industries.

Key Benefits of Cobots

✅ Enhanced Safety – Cobots are built to work next to humans changing how they move in real time to stop accidents.

✅ Unmatched Flexibility – You can reprogram these robots for different jobs, which makes them perfect for production environments that change often.

✅ Budget-Friendly Automation – Cobots are cheaper than regular industrial robots to set up and maintain making it easier for smaller companies to automate their processes.

✅ Increased Output – By handling repetitive jobs, cobots allow human workers to tackle complex issues and come up with new ideas, which helps businesses grow.

Where Do People Use Cobots?

Cobots are causing a shake-up in many industries by boosting efficiency, accuracy, and safety. Here are some main areas where cobot technology is making waves:

- Manufacturing: They have a role in assembly, quality control, and packaging processes.

- Healthcare: They lend a hand in surgeries, help patients recover, and handle dangerous materials.

- Logistics: They make warehouse work better by doing the picking, packing, and sorting .

- Agriculture: They pitch in with planting, harvesting, and keeping an eye on crops to get more out of the land.

Types of Cobots

🔹 Power and Force Limiting Cobots: They stop right away when they touch something to keep everyone safe.

🔹 Speed and Separation Monitoring Cobots: They change how they move based on what’s around them to stay at a safe distance.

🔹 Hand-Guided Cobots: They learn what to do straight from human workers who show them by hand.

🔹 Safety-Rated Monitored Stop Cobots: These robots stop working when people enter their work area and start again once it’s empty.